From Blueprint to Success: A Step-by-Step Guide to Starting Your Own Roof Sheet Business in South Africa

The construction sector in South Africa is currently booming, and this growth creates a massive gap for smart entrepreneurs. Everywhere you look, from the busy streets of Durban to the expanding suburbs of Cape Town, new structures are going up. Because every building needs a top, the roof sheet business is one of the most stable ways to enter the industrial market. If you have been looking for a way to build a legacy while providing essential building materials, this guide is your starting point. We will explore how you can turn a simple idea into a high-capacity manufacturing plant.

Understanding the South African Market Demand

Before you buy your first machine, you must understand who needs your product. The demand for quality shelter is universal, yet the specific needs of South Africans vary by province. In coastal areas like KwaZulu-Natal, homeowners look for materials that resist salt spray and corrosion. Consequently, your roof sheet business must offer specialised coatings like Zincalume or Colorbond to survive the humid air.

Market research involves more than just looking at numbers; you need to visit construction sites and talk to contractors. You will notice that while the roof sheet manufacturing business is competitive, many suppliers have long lead times. If you can deliver faster than the big corporate players, you already have a winning edge. Local builders often prefer buying from someone in their community because it saves them on transport costs and time.

Identifying Your Target Audience

Your customers will likely fall into three categories: small-scale builders, large construction firms, and DIY homeowners. Each group have different priorities. For instance, a homeowner might care most about the roof sheet prices at their local hardware store, like Buco or Cashbuild. On the other hand, a large developer will focus on the roofing sheet description and whether the material meets SABS standards.

To stand out, you should decide whether you want to be a generalist or a specialist. Some entrepreneurs find success by focusing solely on affordable corrugated iron for low-cost housing. Others prefer the high-end market, providing aesthetic steel roofing for luxury estates. Whatever path you choose, ensuring your roof sheet business serves a specific need will help you market more effectively.

Developing a Solid Roof Sheet Business Plan

Success in the manufacturing world rarely happens by accident. You need a document that explains how you will make money and how you will handle risks. A roof sheet manufacturing business plan is not just a piece of paper for the bank; it is your roadmap. It should detail your startup costs, including the price of a roll-forming machine and the initial stock of steel coils.

Your plan must also include a clear roofing sheet business profit analysis. Typically, a small manufacturing plant can see margins of around R11 to R15 per metre, depending on the current price of steel. Because steel is a global commodity, your profit will fluctuate with the rand-dollar exchange rate. Therefore, your roof sheeting business plan must account for these price swings to keep your operations sustainable.

Legal Requirements and Registration

Operating a legal roof sheet business in Mzansi means you have to play by the rules. First, you must register your company with the Companies and Intellectual Property Commission (CIPC). This gives your brand a formal name and allows you to open a business bank account. Additionally, you need to register for tax with SARS and obtain a Tax Clearance Certificate.

Safety is another major factor. Since you will be running heavy machinery, your facility must comply with the Occupational Health and Safety Act. This protects your workers and prevents your business from being shut down by inspectors. It is also wise to look into product liability insurance. If a roof fails due to a manufacturing defect, you want to be covered so that your dream doesn’t turn into a legal nightmare.

Finding the Right Roof Sheet Suppliers

Your business is only as good as the steel you use. To produce a top-quality product, you need to establish relationships with reliable roof sheet suppliers. In South Africa, companies like Macsteel and Safintra are major players that provide raw steel coils. However, as a new entrepreneur, you might also look for specialised roofing suppliers who can offer smaller batches as you scale up.

If you are based in the coastal regions, finding a roof sheet supplier in Durban or a roofing supplier in the Cape Town hub is essential. Buying locally reduces your “roof sheeting cost” significantly because transporting heavy steel across the country is expensive. Always ask for certificates of origin and quality guarantees from your roof suppliers to ensure the steel hasn’t been sitting in a damp warehouse for months.

Comparing Material Costs

When you are sourcing, you will hear terms like ‘galvanised’, ‘Chromadek’, and ‘Zincalume’. Each has a different price of roof sheet attached to it. For example, standard galvanised steel is the most affordable but may rust faster in wet climates. Chromadek, which is pre-painted, is very popular in South Africa for its durability and colour variety, though it increases the roof sheeting prices.

| Material Type | Durability | Relative Cost | Best Use |

| Galvanized Iron | Moderate | Low | Low-cost housing, sheds |

| Chromadek | High | Medium-High | Residential homes, malls |

| Zincalume | Very High | High | Coastal industrial sites |

| Polycarbonate | Moderate | Medium | Patios, skylights |

By offering a range of steel roofing materials, you can cater to different budgets. Keep a close eye on the prices for roof sheeting in the market so that your quotes remain competitive without eating into your margins.

The Technical Side: Machinery and Manufacturing

Setting up your factory is the most exciting part of the journey. You will need a roll-forming machine, which is the heart of your roof sheet business. These machines take a flat coil of steel and press it into the IBR or corrugated profiles we see on rooftops. A decent machine can produce between 10 and 15 metres of sheeting per minute.

Reliability is the best marketing tool in Mzansi.

You also need to understand the roofing sheet manufacturing process. It involves decoiling the steel, feeding it through the rollers, and then cutting it to the exact length the customer needs. Most customers will ask for a specific roof sheet size, ranging from standard 3.6 m lengths to custom 14 m sheets for industrial warehouses. Providing custom lengths is a huge selling point because it reduces the number of joins on a roof, which prevents leaks.

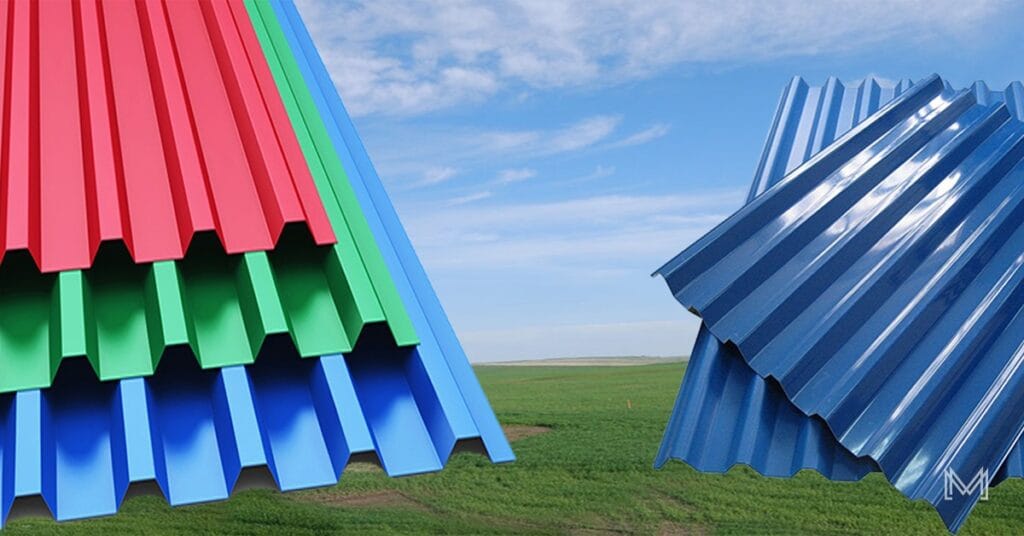

Product Profiles and Descriptions

In South Africa, the two most common profiles are IBR (Inverted Box Rib) and Corrugated. The roofing sheet description for IBR is a square-fluted profile that offers great strength-to-weight ratios. It is the go-to choice for modern houses and factories. Corrugated sheeting, often called “S-Rib”, is the classic wavy look that has been used for over a century.

When a client asks what a roofing sheet is exactly, you should be able to explain the gauge (thickness) as well. Most residential roofs use a thickness of 0.47 mm or 0.50 mm. If you use anything thinner, like 0.27 mm, it is usually reserved for very cheap structures or internal cladding. Knowing these details makes you look like a pro and builds trust with your buyers.

How to Calculate Roofing Sheets for a Building

One way to add value to your roof sheet business is by helping your customers with their orders. Many builders struggle with the maths. They often ask, “How much does a roof sheet cover?” or “What is the size of roofing sheet I need?” If you can answer these questions, they will keep coming back to you.

To teach them how to calculate roofing sheets for a building, you start with the total width of the roof. For example, if an IBR sheet has an effective cover width of 686 mm, you divide the total roof width by 0.686.12. Always remind them to add a 10% buffer for overlaps and wastage. This simple service prevents them from running out of material mid-job and keeps their project on track.

Practical Calculation Steps

- Measure the Length: Find the distance from the ridge (top) to the eave (bottom). This determines the length of each sheet.

- Check the Width: Measure the total horizontal distance the roof covers.

- Account for Pitch: If the roof is very steep, the sheets need to be longer than the flat ground measurement.

- Overlap: Factor in at least one “flute” or wave for the side overlap to ensure it is waterproof.

Knowing how to calculate roofing sheets accurately saves money. When you provide an honest estimate, you prove that your roofing sheet business cares about the customer’s pocket, not just making a quick sale.

Pricing and Staying Competitive in Mzansi

Pricing is a balancing act. If you charge too much, people will go to big retailers like Roof Sheets Buco or Roof Sheet Builders Warehouse. If you charge too little, you won’t be able to pay your electricity bill. You must understand the roof sheet cost from the factory level all the way to the retail shelf.

Currently, roofing tin price and roof metal sheet price are influenced by global supply chains. However, as a local manufacturer, you can save on the “middleman” markups. While a retailer might sell a 6 m IBR sheet for R850, you might be able to sell it for R780 and still make a healthy profit. Always keep an eye on the rooftop sheet price in your local area to ensure you aren’t leaving money on the table.

Understanding the Cost Breakdown

The roof sheeting price is usually quoted per metre or per square metre. In 2025, you can expect galvanised sheets to start around R130 per square metre, while premium powder-coated options can go up to R250. When a client asks for a roofing sheet business in Nigeria or other regions for comparison, remind them that South African steel quality is often higher due to our strict building codes.

If you can deliver faster than the big corporate players, you already have a winning edge.

Your price of roof sheet should also include any extras like ridge capping, flashings, and screws. Many entrepreneurs forget that selling the accessories is where the real “profit” often lies. If you can be a one-stop shop for everything from the sheet to the last washer, your roof sheet business will grow much faster.

Marketing Your Roof Sheet Manufacturing Business

You could have the best product in the world, but if nobody knows about it, your machines will stay silent. In today’s world, a roof sheet business needs a digital presence. You don’t need a fancy agency; just start with a professional Facebook page and a Google Maps listing. Post photos of your machines running and the finished products being loaded onto trucks.

Word of mouth is still king in the South African construction industry. Visit local “hardware stores” and “roofing supply” yards. Offer them a wholesale price if they stock your sheets. You can also partner with roofing sheet companies that handle the installation but don’t have their own machines. By being the reliable manufacturer for smaller installers, you secure a steady stream of orders without having to find every individual homeowner yourself.

Building a Brand with Trust

Use clear language in your ads. Instead of just saying “we sell steel”, use keywords people actually search for, like “sheet roofing prices” or “roofing sheet manufacturing business”. Show people that you understand their problems. If you are in KwaZulu-Natal, mention that you are a roof co Durban alternative that offers faster delivery.

Personal service goes a long way. When a builder calls you at 7 AM on a Monday because they are short by three sheets, try to help them out. That builder will remember your roofing sheet business profit-saving attitude and will likely bring you ten more clients. Reliability is the best marketing tool in Mzansi.

Operations and Managing Your Factory

Running a roof sheet business requires discipline. You need a clean, organised space where you can store heavy coils safely. Steel is heavy and dangerous if not handled correctly. Invest in a proper forklift and ensure your staff are trained to use it. If a coil falls, it can cause massive damage or injury.

Inventory management is your next big task. You don’t want to have too much money tied up in stock that isn’t moving, but you also can’t tell a customer they have to wait three weeks for a common colour like charcoal or dove grey. Start by stocking the most popular colours and profiles. As your roof sheet manufacturing business grows, you can expand your range to include things like business bench stone-coated roofing sheets for a more premium, tile-like look.

Quality Control and Standards

Never compromise on quality. If you produce a batch of sheets that are slightly off-size, don’t try to hide it. A roof that doesn’t fit together perfectly will leak, and your reputation will be ruined. Implement a “check twice, cut once” policy in your roof sheet business.

Check the thickness of every coil you receive from your roofing suppliers. Sometimes a supplier might send a 0.40 mm coil when you ordered 0.50 mm. If you don’t catch this, you will be selling an inferior product to your customers. High standards are what separate a “backyard operation” from a respected roof sheet manufacturing business plan-driven success.

Facing Challenges and Finding Opportunities

Every business has its “hard times”. For a roof sheet business, the biggest challenge is often the rising cost of electricity and raw materials. When the price of steel goes up, you have to decide whether to eat the cost or pass it on to your customers. Transparency is usually the best policy here. Explain to your regular clients why prices are changing, and they will usually understand.

Another challenge is competition from cheap imports. Some roofing sheet companies bring in low-quality steel from overseas that doesn’t last in the South African sun. Educate your customers on why your locally manufactured product is better. Explain that your roof sheeting made from South African materials is designed for our harsh climate. This builds a sense of national pride and trust in your brand.

Embracing Innovation

The future of roofing is changing. People are becoming more environmentally conscious. There is a growing demand for “green” materials. You could look into solar-ready roofing or highly reflective coatings that keep houses cool. Even offering a business bench stone-coated roofing sheet price that is competitive can give you an edge in the luxury market.

Staying ahead of the curve means you are always learning. Attend building expos in Johannesburg or Cape Town. Talk to other roofing sheet business owners. Often, the best ideas come from seeing how others solve similar problems. If you stay flexible and willing to change, your roof sheet business will not just survive; it will thrive.

Hiring and Leading Your Mzansi Team

As your order book fills up, you will need to hire help. Look for people who are reliable and have a good eye for detail. You don’t necessarily need experts in steel; you need people who are willing to learn and show up on time. In a roof sheet business, one small mistake in measurement can waste thousands of rand in material.

Leading a team in South Africa requires empathy and clear communication. Treat your workers with respect, and they will look after your machines as if they were their own. Create a culture of safety and pride. When your team sees a house in the neighbourhood with a roof they made, they should feel proud of their work. This positive energy is the “secret sauce” of any successful roofing sheet manufacturing business.

Scaling Your Business for the Future

Once your first factory is running smoothly, it’s time to think bigger. Could you open a second branch? Maybe a roof sheet supplier’s Cape Town outlet or a distribution point in the Eastern Cape? Scaling requires you to have systems in place so that the business can run even when you aren’t there.

You might also consider diversifying your products. Instead of just sheets, you could start manufacturing the steel purlins that hold the roof up. Or you could look into what the size of roofing sheet that is most popular in neighbouring countries is and start exporting. The sky is the limit for a well-managed roof sheet business.

Investment and Funding

Scaling usually requires capital. If you have kept clean financial records and followed your roof sheet manufacturing business plan, you will find it much easier to get a loan from a bank or a government agency like the SEFA (Small Enterprise Finance Agency). They love supporting manufacturing businesses because you create jobs and support the local economy.

Final Thoughts: Building Your Legacy

Starting a Roof Sheet Business is not a “get rich quick” scheme. It requires hard work, late nights, and a lot of grit. However, there is something incredibly satisfying about building something tangible. Every sheet of steel that leaves your factory is a part of someone’s home, a shop, or a school. You are literally helping to build South Africa.

If you stay focused on quality, treat your customers fairly, and keep a close eye on your costs, there is no reason why you can’t become a leader in the industry. The construction world is waiting for the next generation of entrepreneurs to step up. So, take that first step, register that company, and start making your mark on the skyline of Mzansi.

I can help you further by drafting a sample marketing script for your new business or providing a more detailed breakdown of the machinery costs. Would you like me to create a draft price list for your first set of products?

Frequently Asked Questions: About Starting a Roof Sheet Business

What is the most common roofing profile in South Africa?

The two most common profiles you will encounter are IBR (Inverted Box Rib) and Corrugated sheeting.

What is a key advantage of offering custom roof sheet lengths?

Offering custom lengths reduces the number of joins on a roof, which significantly helps in preventing leaks.

What is a critical legal requirement for running a manufacturing facility?

Your facility must adhere to the Occupational Health and Safety Act because you will be using heavy machinery.

Which two main types of steel coatings are popular in South Africa?

Chromadek, which is pre-painted, and Zincalume are very popular for their durability and appearance.

What is the best way to start marketing a new roof sheet business?

Starting with a professional Facebook page and a Google Maps listing, alongside word-of-mouth referrals, is the best initial digital and traditional marketing approach.